Century's Old Craftmanship

Built From The Heart

We love that we are a small family business & we love to support other small family businesses which is why we buy most of our frames from a father & son partnership, our foams from a family run business & some of our fabrics from a 6th generation family business. We also like to find suppliers local to us so most of our suppliers are within 30 miles of our Rossendale factory.

Every component we use to build our furniture is carefully chosen to ensure our quality & ethics remain; we care deeply about where we source our materials & we ensure that all of our suppliers & products are compliant with UK & EU regulations & that our suppliers also share our quality & ethics in all areas.

Frames

Solid hardwood beech frames

Like any good quality build, you need a good foundation. Our frames are the best foundation you can buy. Every frame is made from solid hardwood which is compliant to UK & EU timber regulations & every joint is glued, screwed & dowelled to ensure it will stand the test of time.

Our decorative frame designs are also made from solid hardwood & then they are stained in your chosen colour. Please see our custom design service page for our range of wood stains to suit any home. Our wooden feet are also made of solid hardwood for maximum strength & durability.

Springs & Suspension

Double tempered no-sag springs

Springs & suspension are also vital elements in furniture construction & we're proud to say that all of our ranges have fully sprung seat platforms. We use double tempered no-sag springs which are all supported & linked together by hand with silent wire to create a suspension system which gives longer-lasting strength & durability compared to elastic webbed seats which are widely used in furniture production.

In our Chesterfield designs we add back springs which are linked together in the same way to give extra strength & comfort & some chesterfield models also have fully sprung arms.

Comfort

Exceptional comfort & durability

Here at Springvale our seat cushions are made from the highest quality foam on the market. There are 3 different densities to choose from, soft, medium & firm but even our softest foam is firmer than most mass produced furniture so please keep this in mind when making your selection.

We also offer fibre cushion fillings & a buttoned seat option. The fibre seat fillings are similar to the filling you would find in a pillow, however our fibre is a denser filling called carded fibre which keeps the cushion fuller for longer. The buttoned seat option is quite firm as it is tightly buttoned like a chesterfield but it's a beautiful finish for those wanting a little more detail.

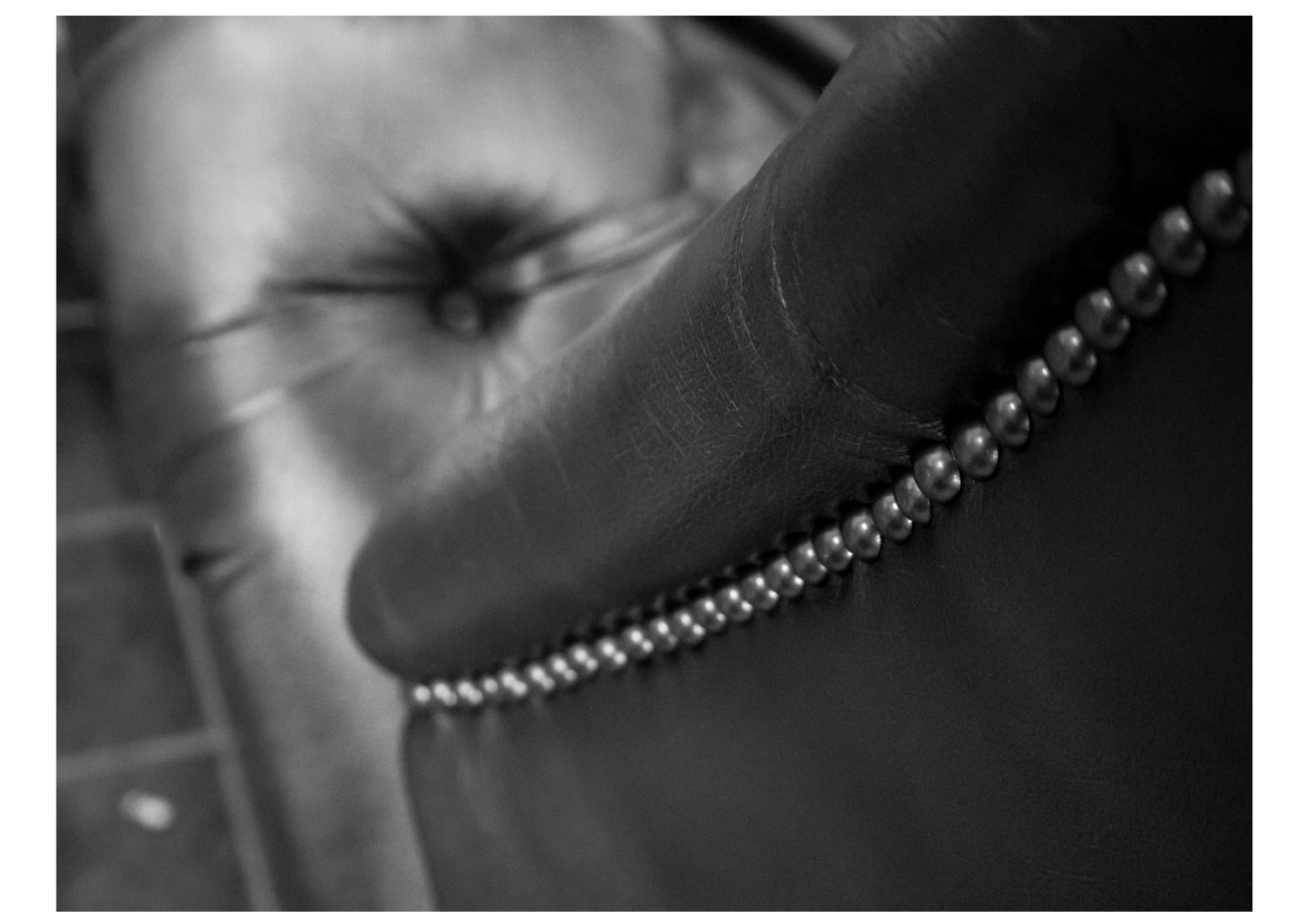

Buttons & Studs

Unique finishing touches

No two homes are the same which is why we offer the largest selection of finishes on the market. We offer 10 different stud colours, 11 wood stains & a wide range of button & piping options to ensure your furniture will look exactly how you want it to look. What’s even better is that we don’t charge any extra for a different stud or wood colour which makes customising your furniture even more affordable. You can also choose to add buttons & studs for more detail or take them off completely & replace with a plain border & piping for a more simple look.

With our chesterfield models, we use a traditional deep buttoning technique which ensures the buttons are fastened into the frame to a depth of 2-4cm which makes the chance of a button coming loose almost non-existent.

Every item of Springvale furniture is also finished with a solid brass plaque of quality on the side as the perfect finishing touch.

Castors & Bun feet

Feet for any occasion

We offer so many different feet, because although they are under your sofa, they shouldn’t be an afterthought. We offer solid wooden feet in different shapes & sizes which are all available in any of the 11 wood stains, we offer metal feet in a range of shapes & finishes & we offer castor legs in varying finishes & styles.

We also offer a choice of plain or turned legs on some of our occasional chairs & bar stools & our Wing Chairs also come with the Queen Anne legs as standard, these can all be stained in any of our 11 wood stains to ensure every piece is made perfect for your home & individual style.

Leather

Top quality leather hides

The leather hides we use are always from a trusted source & are always produced as a by-product of the meat industry. We will never use any other types of leather hides or skins.

The leather hides we use are all of the highest quality & the way we categorise our leathers is by the finish. As you can see from our leather options, we have a wide range of finishes which are all individually priced. We have reduced the colour choice online but there are many more leather colours & finishes available, so if you don’t see your perfect colour online please call our sales team on 01706 211830.

The leather ranges available are:

Antique – this is a traditional hard-wearing two-tone hand finished leather available in 6 colours

Austen – this is a natural semi aniline leather with a mottled two-tone effect available in 5 colours

Brunel – this is a hand buffed very natural soft distressed leather available in 5 colours

Old English – this is a natural wax finished semi aniline leather available in 11 colours

Saloon – this is a heavy distressed hard-wearing finish available in 5 colours

Shelly – this is a hard-wearing corrected grain leather available in 22 colours

Fabrics

Luxurious fabrics

Any of our ranges can be made in any fabric or leather. We offer an unlimited range of fabrics in our showroom but we have chosen our favourite ranges to offer online.

We have included 100% wool ranges which include plain, plaid & herringbone, we have also

included the exclusive HARRIS TWEED wool range which is supplied fully branded with the HARRIS TWEED labels. We have included some bolder fashion fabric designs for statement pieces & we have also added some hard-wearing plain fabric ranges in cotton/linen finishes & plush velvets.

We feel the fabric ranges shown online offer something for every home & style but if you don’t see what you’re after please feel free to call our sales team on 01706 211830 where we can source any bespoke fabrics you may be looking for.

Book a Showroom Appointment

1 hour showroom appointment with one of our furniture specialists at our Rossendale showroom.

Book NowWhy Choose Us

0%

Finance available when paying with Paypal

10yr

10 year build quality guarantee

21day

21 day express UK delivery option available

GB

Handbuilt in Lancashire Great Britain